Add:No 681,west road of huan cheng,1122 ,

Contacterer:Tyler Yu 于虎

Telephone/Fax:86-574-88173605

Mible手机:86-18969805910

Email邮箱:tyler@nb-brilliance.com

Web:http://www.nb-brilliance.com

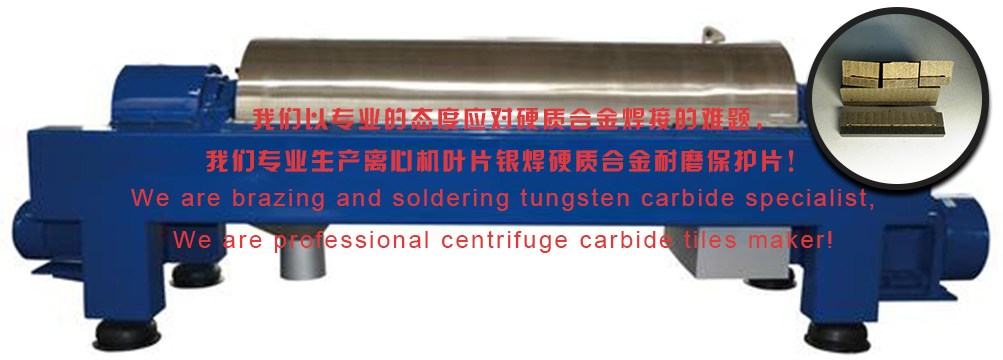

设备重要工作面的保护/The protection of equipment's important working surface

很多设备的工作面处于恶劣的工作环境,要承受很大的磨损,比如螺旋传输机,卧螺离心机的螺旋推进器等等。如果设备工作面不进行耐磨损保护的话,整个设备的使用寿命和维护周期会极大的缩短。

The working surface of many equipments is in a bad working environment and suffers great wear and tear, such as screw conveyors, screw propellers of decanter centrifuges and so on. If the equipment’s working surface is not wear-resistant protection, the entire equipment life and maintenance cycle will be greatly shortened.

在众多的保护方案中,利用硬质合金的超高耐磨性是效果最好的方案,具有保护效果好和维护方便的双重优点。

Among the numerous protection schemes, the ultra-high abrasion resistance of tungsten carbde is the best solution, with the dual advantages of good protection and easy maintenance.

具体做法是通过特殊特种钎焊技术将硬质合金片和不锈钢基体焊接在一起形成耐磨片,再将此耐磨片焊接在设备工作面的表面。

The specific method is to braze the tungsten carbide and the stainless steel backer together to form a tungsten carbide tile, and then weld the carbide tiles on the working surface of the equipment.

那么为什么不把硬质合金直接焊接在设备工作面的表面呢?这是因为硬质合金的焊接难度很大,稍有不慎就会造成硬质合金断裂,或者焊接强度不够。所以,用不锈钢基体作为中介是十分必须的。

So why not brazing the carbide inserts directly to the surface of the equipment? This is because it is very difficult to braze tungsten carbide inserts. A slight carelessness can cause the carbide to fracture, or the brazing strength is not enough. Therefore, the use of stainless steel matrix as an intermediary is very necessary.

那么,添加了耐磨片保护后,能达到什么效果呢?这和设备的工作环境有关系,但总的来说,有了耐磨片的保护,设备工作面的维护周期会成倍增加,可能有2-3倍,甚至更多。

Then, what effect can be achieved after adding the carbide tiles? This is related to the working environment of the equipment, but in general, with the protection of the carbide tiles, the maintenance cycle of the working surface of the equipment will increase exponentially, which may be 2-3 times or even more.

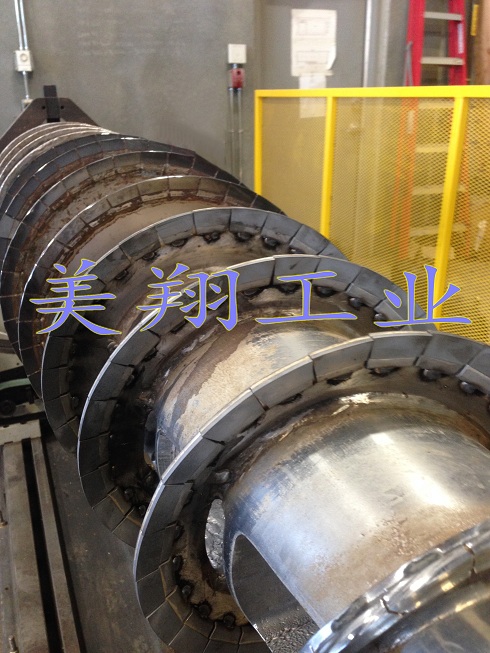

用于卧螺离心机的耐磨片/the carbide tiles for centrifuge

卧螺离心机的螺旋推进器,耐磨片对它来说是非常必需的。

screw propellers of decanter centrifuge,the carbide tiles is very necessary!