Add:No 681,west road of huan cheng,1122 ,

Contacterer:Tyler Yu 于虎

Telephone/Fax:86-574-88173605

Mible手机:86-18969805910

Email邮箱:tyler@nb-brilliance.com

Web:http://www.nb-brilliance.com

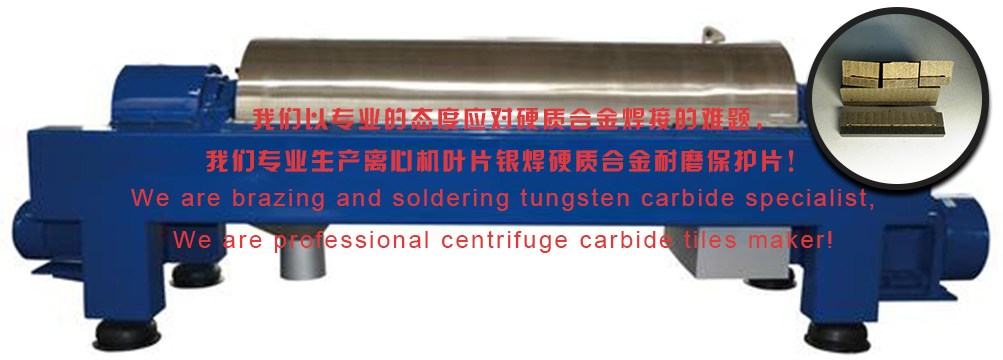

Screw protection of drilling decanter centrifuge

There are mainly 3 types protection for solids separation centrifuge propeller screw. Many customer do not know the difference of them and wondering about how to choose the suitable one for its centrifuge. Below is the elaborate for the difference of the 3 screw protection design.

1) Tungsten carbide hard surface for screw protection: It is the most common type in China. Nearly all other companies make this type, besides GN Solids Control Co., Ltd. It is easy for process, and cost lower. But the height of the welded Tungsten carbide on the screw surface is very thin, only around 1mm. This type of centrifuge is cheaper, but not good at anti-friction and anti-abrasive. If the solids content high, after half year or 1 year, not more than 2-year time, the Tungsten carbide hard surface will be worn out and the centrifuge will lose balance. The users need to open the centrifuge bowl, welding again to maintenance it and make dynamic balance again. It requests the operator with a higher specialty, and more cost on maintenance.

Tungsten carbide hard surface for screw protection

2) Interchangeable ceramic tiles for screw protection: It is interchangeable small pieces, with exact same weight and dimension. It is strong. And mostly, it has a higher function on anti-abrasive under heavy Acid / Soda corrosion, even better than Tungsten Alloy Tile. Therefore it is mostly used for mining industry. Its cost higher than Tungsten carbide hard surface. The height of the each ceramic tile is reach to 4mm, much more anti-friction than Tungsten carbide hard surface.

Users only need to replace the worn out piece with new one, new need to make dynamic balance. Easy for maintenance.

Interchangeable ceramic tile for screw protection

3) Tungsten Alloy Tile for screw protection: It is the most perfect one and most anti-friction. It is interchangeable small pieces, completely made from each piece with exactly the same weight and dimension. It is the most expensive type, as the material is expensive and a higher request on machining Précising. The height of the each ceramic tile reaches to 4mm, much more anti-friction than Tungsten carbide hard surface, and even strong than ceramic tiles. It is mainly used for barite recovry, fine solids separation and drilling waste managment field.

Users only need to replace the worn out piece with new one, new need to make dynamic balance. Easy for maintenance.